LOWCAV and LOWNOISE X-TRIM Cage valves are engineered for those services where is required pressure and flow rate control with reduced cavitation and noise issues.

GENERAL CONSTRUCTION

Cage Valves model LOWCAV and LOWNOISE are mainly suitable for liquid, steam and gas applications in standard and severe services (with low/cryogenic and high temperature). A dedicated designed X-TRIM is optimized for cavitation control (LOWCAV) and noise reduction (LOWNOISE) with very high rangeability and high FL values in throttling service. X-TRIM design for extreme applications!

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

Three/two pieces bolted body with plates or pin |

|

Trim |

Cage X-trim optimized from cavitation control (LOWCAV) or noise reduction (LOWNOISE) |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 (for shutoff) and FCI 70-2 / IEC 60534-4 |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

|

Sealing |

Regulation: Unidirectional Shut-off: Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request). Metal seated with Tungsten or Chrome Carbide coatings |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

On request |

|

Seat grease injectors |

Not foreseen on this model |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

On request |

|

Valve operation |

Gear box with positioning indicator or self-adjusting closed ring control system with actuator and positioner |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D/ISO 5208 and FCI 70-2 / IEC 60534-4 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-196° to > 700°C (-320° to > 1292°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 600) |

|

Size range |

DN50 (2″) to DN600 (24″) other on request |

|

End connections |

ASME B16.5 ≤ DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Hub&Clamp |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D |

|

Size |

NPS 1/2″- 10″ |

|

Pressure |

Class 150 – 2500 |

|

Material |

WCB, LCB, CF8/CF8M, CF3/CF3M, A105, LF2, F304/F304L, F316/F316L, F347, F51, F53, F55, F60, INC 625, INC 825, INC718 |

|

Design & Manufacture Std. |

API 608, BS 5351, ASME B16.34 |

|

Face to Face Std. |

ASME B16.10, API 6D, API 6A, DIN 3202 |

|

End Connection Std. |

ASME B16.5, DIN 2543-2546, Pups |

|

Test standard |

ISO5208, API 598, BS 6755 |

|

Structure Type |

Anti blow out stem, fire safe, Soft seat, Metal seat |

|

Operated Way |

Lever, Gear, Pneumatic, Electric, Hydraulic |

|

Size |

2″ – 16″ |

|

Pressure |

Class 150 – 2500 |

|

Material |

WCB, LCB, CF8/CF8M, CF3/CF3M, A105, LF2, LF3, F51, F55, F60 |

|

Design & Manufacture Std. |

API 6D, ASME B16.34, ASME VIII |

|

Face to Face Std. |

Manufacturer standard |

|

End Connection Std. |

ASME B16.5, ASME B16.25 |

|

Test standard |

ISO5208, API 6D, API 598 |

|

Operated Way |

Gear, Pneumatic, Electric, Hydraulic |

Diverter and mixing valves ideal for flow switching and bypass operations with seals at every port, widely used in the Petrochemical and Refinery industries with highly viscous media or processes that have to continuously back flush their process lines.

GENERAL CONSTRUCTION

Multiport valves are engineered to switch critical processes and difficult media. They are often in 3, 4, 5 or 6 way construction with T, L or Y port, mostly used to split or combine process flows or to switch medium between alternative pieces of process equipment such as pumps, filters, strainers, meters, heat exchangers or complete pipelines, direct flow out of or into storage tanks, shutoff flow from different locations, in severe operating conditions with high flow rates, at high pressure and critical temperature conditions. Multiport valves can also be tandem or manifold mounted to further centralize control, also combined with smart positioners, jacketing, and automated control panels, suitable for electric, hydraulic or pneumatic actuation.

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

Bolted body |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function |

|

Pressure relief |

Not foreseen for this model |

|

Sealing |

Metal seated with Tungsten Carbide , Chrome Carbide or Stellite coatings Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

In line with temperature conditions |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-196° to > 700°C (-320° to > 1292°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2″) to DN1400 (56″) |

|

End connections |

ASME B16.5 ≤ DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Clump (HUB) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

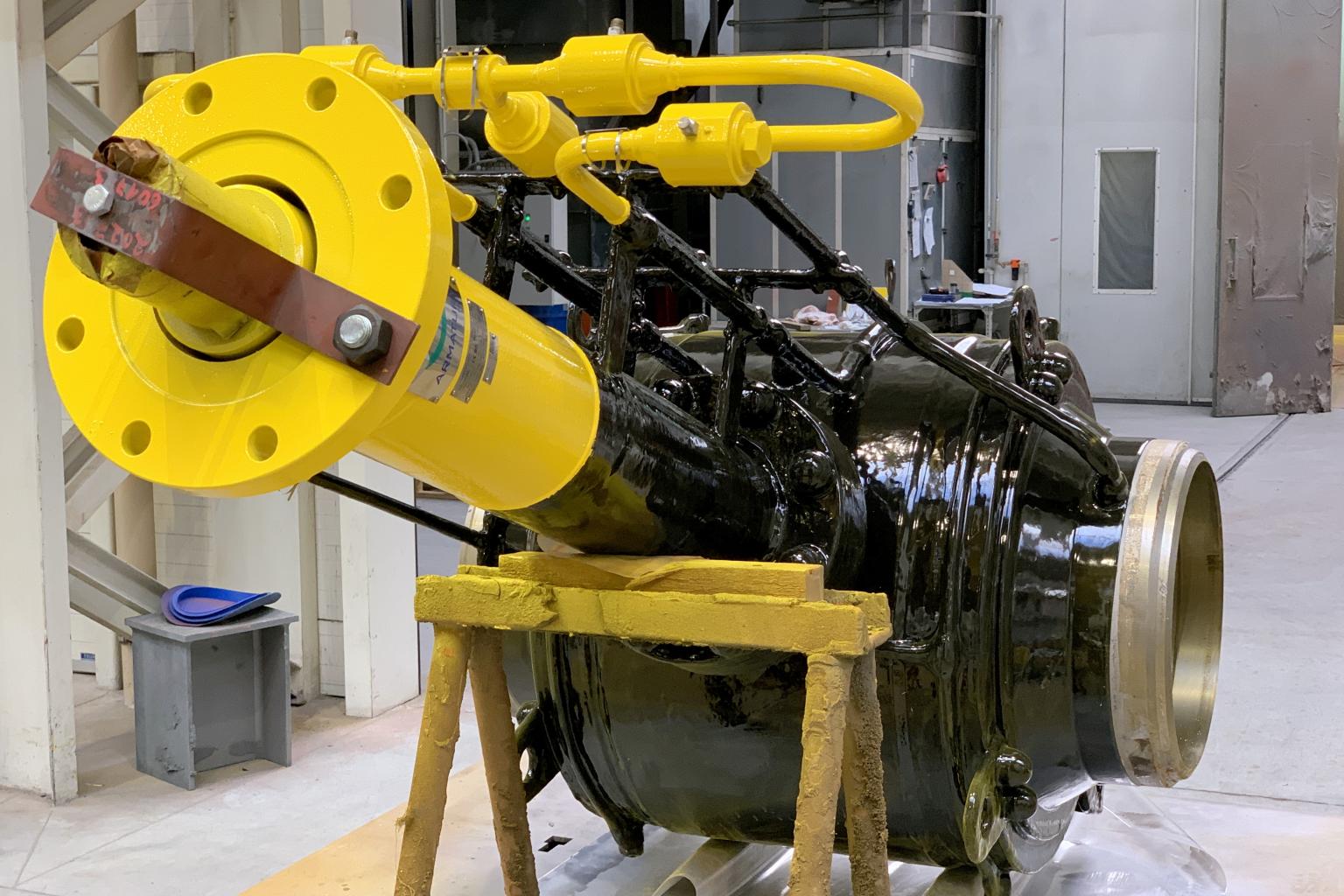

Valves suitable for Oil & Gas production, processing, transportation, distribution, chemical and petrochemical refining on above ground and below ground installations.

GENERAL CONSTRUCTION

Trunnion ball valves have the obturator bounded by trunnions which do not allow axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to sizes and pressures. Fully welded constructions, both flanged or with welded ends, are a preferable solution when no maintenance is required on above ground or below ground (buried) installations and allows a real 0 leakage feature.

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

Fully welded body |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

|

Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request) Metal seated with Tungsten or Chrome Carbide coatings Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request. |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Seat grease injectors |

Included for sizes = DN150 (6″), < DN150 upon request |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

Not foreseen for this model |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-50° to 200°C (-58° to 392°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2″) to DN1400 (56″) |

|

End connections |

ASME B16.5 = DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.47 A = DN650 (26″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Clump (HUB) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D, API 6DSS |

Valves suitable for Oil & Gas production, processing, transportation, distribution, chemical and petrochemical refining on above ground and below ground installations.

GENERAL CONSTRUCTION

Trunnion ball valves have the obturator bounded by trunnions which do not allow axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to sizes and pressures. Erreesse modular double block & bleed (DBB) valves are engineered and manufactured to provide a compact and reliable alternative to multiple instrument valve systems, reducing leak paths and saving installations and maintenance costs.

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

Two or Three piece bolted body |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

|

Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request) Metal seated with Tungsten or Chrome Carbide coatings Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request. |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Seat grease injectors |

Included for sizes = DN150 (6″), < DN150 upon request |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

Not foreseen for this model |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-50° to 200°C (-58° to 392°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2″) to DN1400 (56″) |

|

End connections |

ASME B16.5 = DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.47 A = DN650 (26″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Clump (HUB) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D |

Valves suitable for Oil & Gas production, processing, transportation, distribution, chemical and petrochemical refining.

GENERAL CONSTRUCTION

Trunnion ball valves have the obturator bounded by trunnions which do not allow axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to sizes and pressures.

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

Two or Three piece bolted body |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

|

Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request) Metal seated with Tungsten or Chrome Carbide coatings Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Seat grease injectors |

Included for sizes = DN150 (6″), < DN150 upon request |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

Not foreseen for this model |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-50° to 200°C (-58° to 392°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2″) to DN1400 (56″) |

|

End connections |

ASME B16.5 = DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.47 A = DN650 (26″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Clump (HUB) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D, API 6DSS |

Special valve constructions to allow easy on-site maintenance and disassembly with quick access to ball and seats for inspection and repair.

GENERAL CONSTRUCTION

Top Entry valves are suitable for compression and re-injection systems, transmission pipelines, metering skids, Pig-launchers and receiving stations, Off- Shore and On-Shore platforms, gas storage and separations systems suitable for a wide range of high risk industry applications from severe abrasive and slurry to high temperature and cryogenic services, from subsea and LNG plants to topside installations. ERREESSE Top Entry valves can be welded directly onto the pipeline or to the manifold.

MATERIALS OF CONSTRUCTION

STANDARD FEATURES

|

Construction |

One piece bolted bonnet |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate B,C, D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent overpressure in body cavity (self-relieving seats) |

|

Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request) Metal seated with Tungsten or Chrome Carbide coatings Primary metal secondary soft (PMSS) with differential hardness between the ball and seat to prevent galling of the substrate Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes = DN150 (6″) < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Seat grease injectors |

Included for sizes = DN150 (6″), < DN150 upon request |

|

Lifting points |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Support feet |

Included for sizes = DN150 (6″) or on valves of 250 kg min |

|

Stem extension |

Not foreseen for this model |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156 Non-destructive testing (NDT) to API 6D, ASME B16.34 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-50° to 200°C (-58° to 392°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2″) to DN1400 (56″) |

|

End connections |

ASME B16.5 = DN600 (24″) Flanged RF,FF,RTJ MSS-SP-44 = DN550 (22″) Flanged RF,FF,RTJ ASME B16.47 A = DN650 (26″) Flanged RF,FF,RTJ ASME B16.25 Butt-Weld BW Clump (HUB) |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D, API 6DSS |